When it comes to Very Narrow Aisle (VNA) operations, choosing the right equipment is only half the story. The other half? The floor beneath it—and the guidance system that makes automation possible.

At Applied, we help clients unlock the full potential of VNA trucks by delivering engineered flooring systems that enable flawless wire guidance—with precision, reliability, and long-term performance built in.

Why So Many Warehouses Are Moving to Wire Guidance

Wire guidance is the backbone of modern warehouse automation. It enables VNA trucks to steer automatically along embedded wire paths, allowing operators to work faster, safer, and more efficiently. Unlike rail systems, wire guidance keeps your aisles clear, your vertical cube intact, and your layout flexible.

But here’s the catch: If the floor isn’t up to spec, the entire system fails to deliver.

Poor flatness leads to:

- Loss of wire tracking and signal dropouts

- Slower travel speeds

- Fork misalignment and mast sway

- Increased wear on wheels, axles, and equipment

- Damaged racking, inventory, and ultimately—your bottom line

That’s where we come in.

We Engineer Floors for VNA operations – Not Just Wire Guidance

We engineer high-performance, Fmin-certified floors that support wire-guided automation from day one. Our work ensures that your investment in VNA trucks pays off—with maximum uptime, higher throughput, and lower lifetime costs.

Our clients value most:

- Precision Flatness for Automation We deliver floors that meet or exceed Fmin 75–100 standards, critical for safe and efficient VNA operation. If your floor is underperforming, we use precision grinding and advanced self-leveling systems to bring it up to spec—no guesswork, no shortcuts.

- End-to-End Wire Guidance Preparation From cutting and embedding 16 AWG guidance wire, to epoxy sealing, loop placement, our team handles every technical detail—ensuring your guidance system works flawlessly.

- Integrated Safety Features We coordinate with your integrator or OEM to ensure features like End Aisle Control (EAC) and Manual Wire Sense are supported and aligned with floor magnet placement, layout specs, and safety requirements.

- Automation-Ready from Day One Whether it’s a new facility or retrofit, we align every layer of your floor—from substrate prep to final finish—to support automation systems like VNA trucks, ASRS, AMRs, or AGVs.

Key Installation Considerations

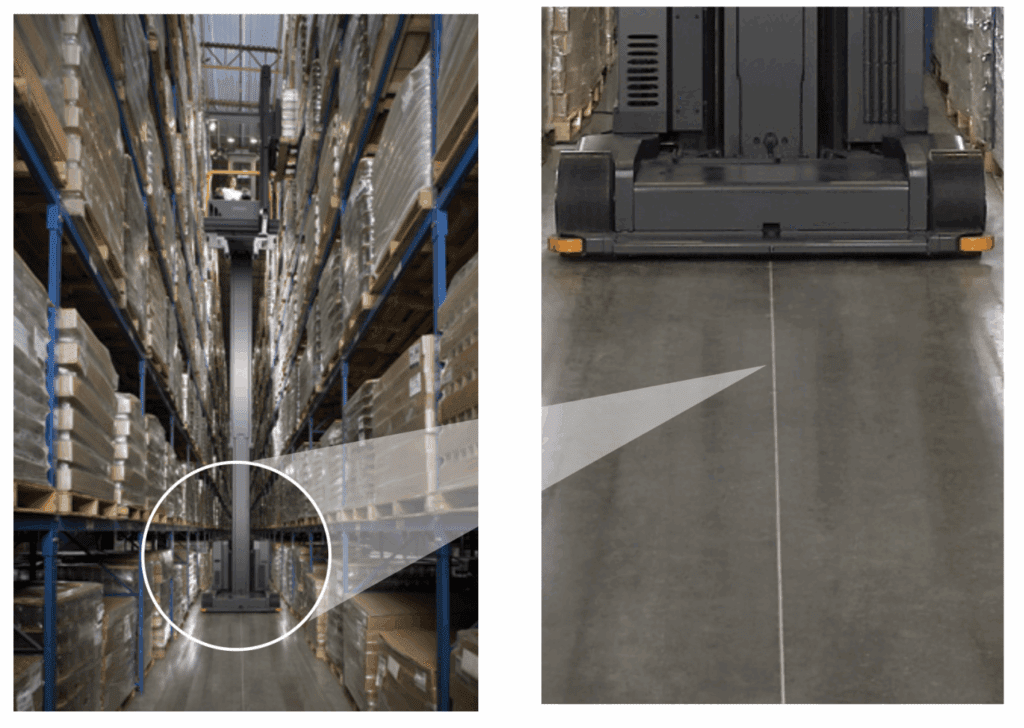

To ensure your wire guidance system is installed correctly and your VNA trucks are operating at peak efficiency, I’d like you to observe the behavior of your trucks. When guidance is done right, trucks acquire the wire seamlessly—typically within a few feet of entering the aisle—and maintain consistent automatic steering without drifting, hesitations, or manual corrections. There should be no unexpected slowdowns, signal dropouts, or diagnostic alarms. The system should enable full-speed travel based on the truck’s lift height profile, eliminating the need to limit speed due to floor inconsistencies or tracking issues artificially.

The quality of floor installation plays a critical role in this performance. A properly engineered floor meeting Fmin 75–100 tolerances ensures a stable, flat, and defined traffic path, preventing mast sway, wheel lift, or signal interruptions. Wire should be embedded at the correct depth, looped at expansion joints, and isolated from steel reinforcement. Signal strength must be verified using a calibrated field meter, and truck calibration should match the installed frequency and layout. These technical details are the foundation for safe, reliable guidance and high-speed operation.

Finally, operator experience often tells the story. When guidance is done right, operators trust the system—they feel in control, avoid manual overrides, and report reduced fatigue. There’s no need for workarounds or aisle-specific exceptions. At Applied Flooring, we ensure all elements—from flatness to wire signal and magnet placement—are aligned with your automation goals, giving you the confidence that your VNA system will perform at full potential without compromise.

Let’s make sure your next project drives automation without limits—starting with the floor under your feet.