Joints are an essential feature of industrial flooring designed to control where and how a concrete slab moves as it naturally expands and contracts. However, seeing open joints can often raise concerns, making facility managers question whether this signals a serious problem. In this edition, we’ll address common questions about concrete joints and explore why maintaining them properly is crucial for avoiding long-term issues.

Why Do Joints Widen?

First, it’s essential to know that joints aren’t a defect in your flooring. Concrete naturally shrinks as it cures and responds to environmental changes such as temperature fluctuations. As a result, joints may widen over time due to concrete shrinkage, changes in temperature, or heavy equipment movement. The ACI 302.1R-04 guidelines state that these openings are expected during the design phase and should not be viewed as structural failures. They aim to prevent random cracking by allowing the concrete to move as needed.

Does This Indicate a Failure?

Seeing open joints isn’t necessarily a sign of failure, but they can become problematic if neglected. Over time, widened joints can lead to spalling (cracking or flaking at the edges), erosion, and other damage. According to the American Concrete Institute (ACI 302.1R-04), proactive measures should be taken to ensure that joints continue functioning as intended. What might seem like a minor issue today could become an expensive problem down the road if left unchecked.

When Open Joints Become Damaged

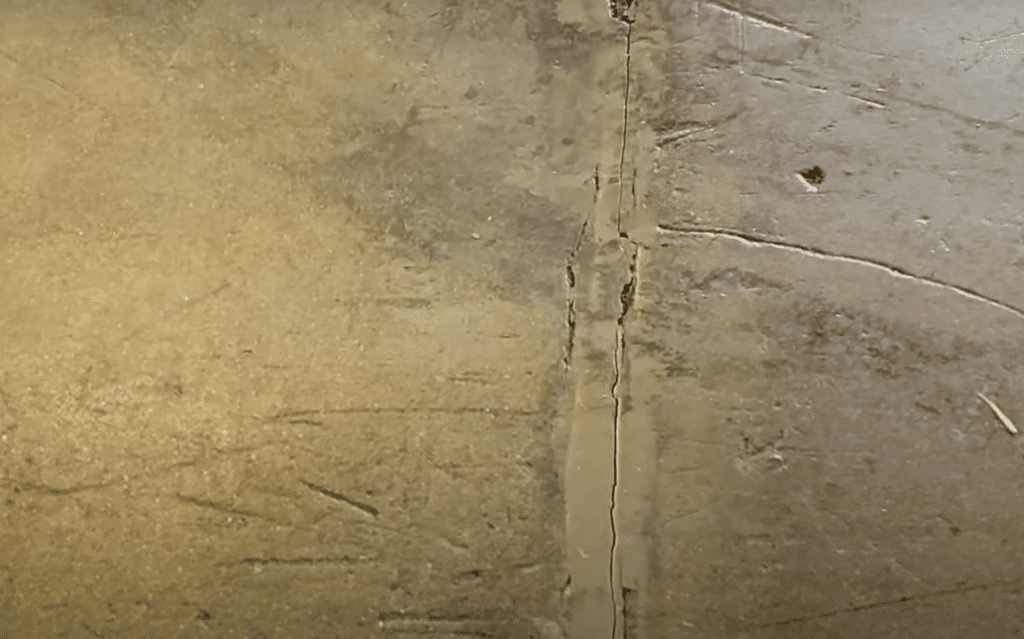

Open joints can be more than just a visual concern—if not properly managed, they can be the starting point for serious structural issues. Inadequate maintenance or flaws in joint design can lead to excessive widening and edge spalling, often caused by heavy machinery or high-impact loads. This mechanical damage can significantly weaken the joint edges, making them prone to further deterioration.

If joints are left unchecked, the resulting spalling and edge erosion can impact the integrity of the entire floor, leading to costly repairs and operational downtime. For severely damaged joints, the best solution is a specialized joint repair system that reinforces and restores the joint. These systems often involve high-strength, fast-setting repair materials that can bond with existing concrete, protect against future damage, and extend the lifespan of the joints.

The Role of Maintenance: Polyurea Refill

Regular joint maintenance is key to extending the life of your concrete floors. A best practice is to refill joints with a semi-rigid filler, such as polyurea. The polyurea offers flexibility and strength, handling minor joint movement while protecting the edges. Regular maintenance is crucial—joints are at higher risk of damage without it. Routine inspections should be conducted, especially in high-traffic areas, to identify and refill any joint issues promptly.

Key Takeaways:

- Joints Open by Design: They are meant to handle natural movements caused by shrinkage, temperature changes, and heavy loads.

- Not a Failure, But a Warning: While open joints aren’t a failure, neglecting them can lead to costly damage.

- Follow ACI 302.1R-04 Recommendations: Your concrete floor should be designed with adequate joints and undergo regular inspections and maintenance.

- Timely Repairs with Polyurea: Refill joints as needed to protect against edge deterioration and maintain your floor’s longevity.

- Address Damaged Joints Quickly: If you notice extensive joint damage or spalling, consider using a specialized repair system to restore and reinforce your floor.

Common Questions:

- When Should Joints Be Refilled? – Joints should be refilled when their width exceeds the designed tolerance or when visible edge damage occurs.

- Does Joint Maintenance Extend the Floor’s Life? – Absolutely. Proper maintenance, including joint refilling, can significantly extend the lifespan of your floor and save on repair costs.

- What Happens if Maintenance Is Delayed? – Without timely maintenance, joints are more likely to suffer spalling and erosion, leading to more extensive and expensive repairs.

Final Thoughts

Concrete joints often need to be better understood. Open joints aren’t inherently problematic if they’re properly maintained and part of a well-designed system. However, neglecting them can lead to significant damage. By following ACI 302.1R-04 guidelines, committing to routine inspections, and timely refilling with polyurea, you can protect your investment and avoid unnecessary disruptions to your operations. And if your joints have already suffered damage, don’t wait—using a specialized repair system can restore joint integrity and extend the life of your flooring.

If you’d like to learn more about concrete maintenance or have questions about your facility’s flooring needs, feel free to contact us, or stay tuned for more insights in our upcoming newsletters.