As warehouse owners look to maximize storage density and throughput, Very Narrow Aisle (VNA) turret trucks are becoming essential tools in high-performance logistics environments. However, many facilities overlook a fundamental success factor: the floor beneath the equipment.

To achieve safe, efficient, and reliable performance from your VNA system, especially when using wire guidance, your floor must meet strict flatness and levelness tolerances tailored for Defined Traffic Path (DTP) operations.

Why Floor Tolerances Matter for VNA Trucks

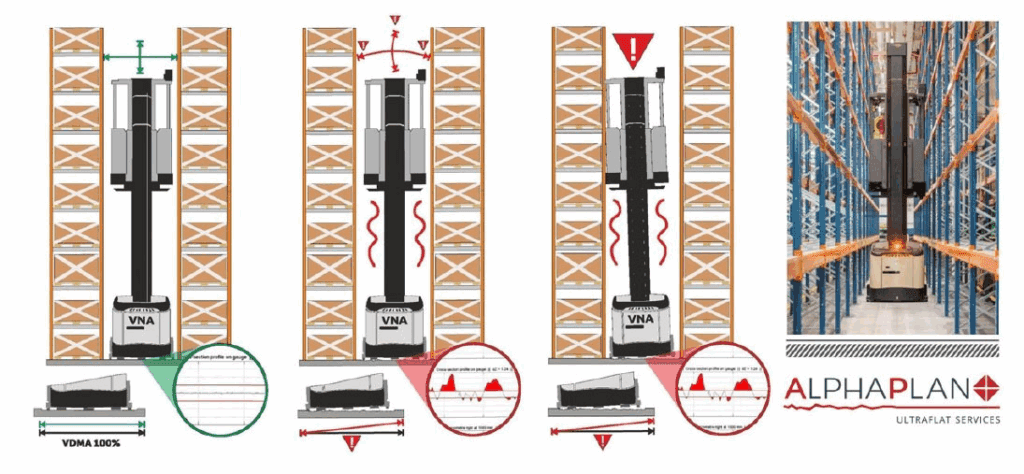

VNA turret trucks travel along fixed, repeated wheel paths in narrow aisles. Unlike traditional forklifts, they are far more sensitive to surface deviations. Even minor irregularities in floor elevation can lead to:

- Mast sway and fork misalignment during high lifts

- Loss of wire guidance signal or tracking failures

- Slower travel speeds and forced deceleration

- Increased wear on wheels, axles, and electronic systems

- Operator fatigue and product damage

To avoid these issues, floors must comply with Fmin tolerances, a standard explicitly used for defined traffic applications.

Understanding Fmin Tolerances

Fmin is a numeric index that quantifies the flatness and levelness of a floor along a defined wheel path. It is different from the more general FF/FL system used for free-moving equipment.

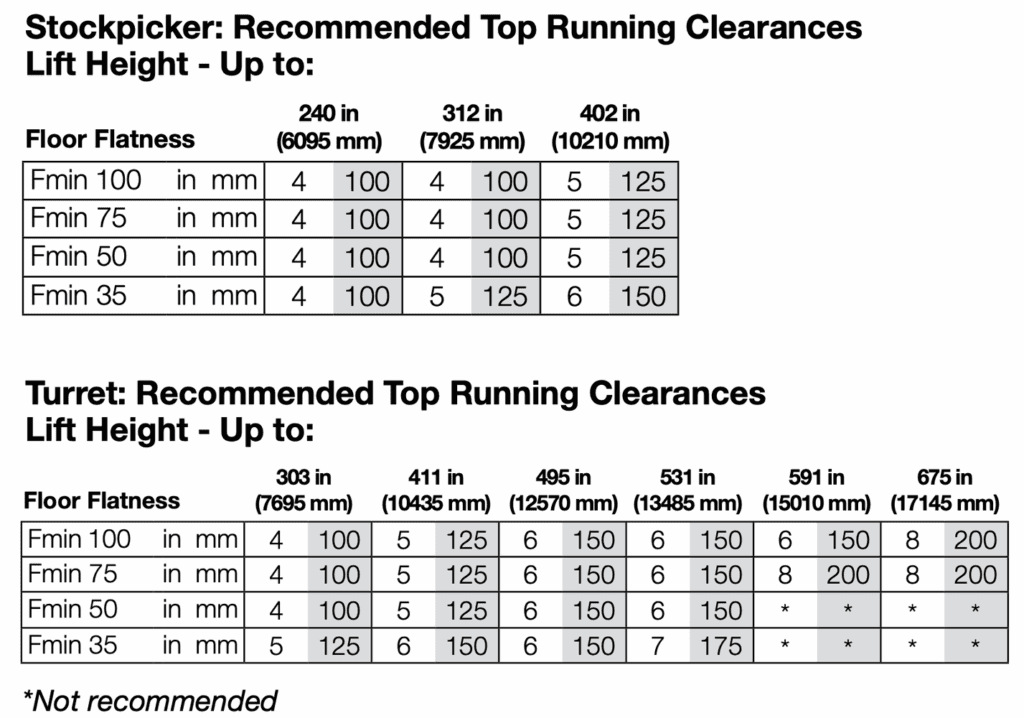

Based on OEM Guidelines, the recommended tolerances are:

⚠️ Important: While VNA trucks may technically operate on floors below Fmin 50, performance will be significantly degraded, and operating costs will increase due to mechanical wear and speed limitations.

What Happens If You Ignore Flatness Requirements?

Operating VNA trucks on floors that do not meet the required Fmin tolerance can result in:

- Severe truck vibrations

- Reduced operator confidence

- Intermittent signal loss for wire-guided systems

- Frequent maintenance or reprogramming

- Downrating of lift capacities due to instability

- Racking damage from steering misalignment

Other Factors That Affect Running Clearance

Beyond general flatness, several design and operational details also influence safe VNA operation:

- Lift height – The higher the forks go, the tighter the tolerance needed

- Load stability – Overhangs, shrink wrap, and weight affect truck sway

- Housekeeping standards – Misplaced pallets or debris alter clearance

- Load handler length – Longer forks magnify floor variation impact

All of these must be accounted for when evaluating or correcting a floor for VNA readiness.

How to Achieve the Required Flatness

Achieving or correcting Fmin compliance typically involves:

- Precision grinding of the floor surface

- Laser floor profiling to map and validate tolerances

- Self-leveling overlays (screed) for large area correction

- Joint and crack treatment to maintain consistent wheel paths

- Installation of defined wheel paths with epoxy joint filling, where necessary

Bottom Line for Floor Owners

If you’re planning to implement VNA turret trucks—especially wire-guided systems—you must design, build, or upgrade your floor to meet Fmin 65–100 tolerances. This is not optional if you want full-speed, high-reach, and trouble-free automation performance.

At Applied, we specialize in evaluating, correcting, and delivering high-tolerance, automation-ready slabs that meet or exceed the requirements. From concrete survey to QA-certified grinding systems and documentation, we ensure your floor is ready for the equipment you’re investing in.

Are you unsure if your floor is ready for VNA? Let’s survey it. We’ll give you a straight answer—and a plan to get it right.