Controlling the quality of repaired cracks and joints on polished concrete is essential to ensure a smooth, aesthetically pleasing, and durable finished surface. It’s crucial to perform crack and joint repairs on polished concrete floors to maintain their safety, integrity, and aesthetics.

You can begin by thoroughly assessing the extent and type of damage. Different types of cracks (e.g., shrinkage cracks, settlement cracks, structural cracks) may require other repair methods. Understanding the cause of the cracks helps in selecting the appropriate repair approach.

Surface Preparation

Clean the Surface: Ensure the concrete surface is free of dust, dirt, and contaminants. This may require pressure washing or shot blasting.

Remove Loose Material: Use appropriate tools to remove loose or deteriorated concrete around the cracks and joints. This might involve chiseling, grinding, or saw-cutting.

Select the Right Repair Materials

-

Epoxy Fillers:

For narrow cracks, epoxy-based fillers are often recommended. They provide strong adhesion and durability. Ensure the epoxy filler matches the color of your concrete.

-

Polyurethane Sealants:

Polyurethane sealants are flexible and suitable for joints that need some movement capability.

-

Concrete Patching Compound:

For more extensive repairs, use a concrete patching compound that matches the composition and appearance of the existing concrete.

Proper Application

For a successful repair, it is essential to adhere to the manufacturer’s instructions when mixing and applying repair materials. When filling cracks and joints, ensure you reach the correct depth and eliminate air pockets or voids. After the repair, smooth the surface to match the surrounding concrete texture. To achieve maximum strength, it is necessary to properly cure the repaired area by following the recommended curing times. Lastly, inspect the repaired areas closely for imperfections, such as air bubbles, unevenness, or color mismatches. Make any necessary touch-ups before proceeding with the final polishing steps.

Grinding and Polishing

After the repairs have fully cured, it is crucial to grind the entire surface to create an even appearance. To achieve the desired level of smoothness and sheen, gradually progress through finer grits. Afterward, apply a high-quality concrete sealer compatible with the polishing process and offer good adhesion to protect the polished surface and repaired areas.

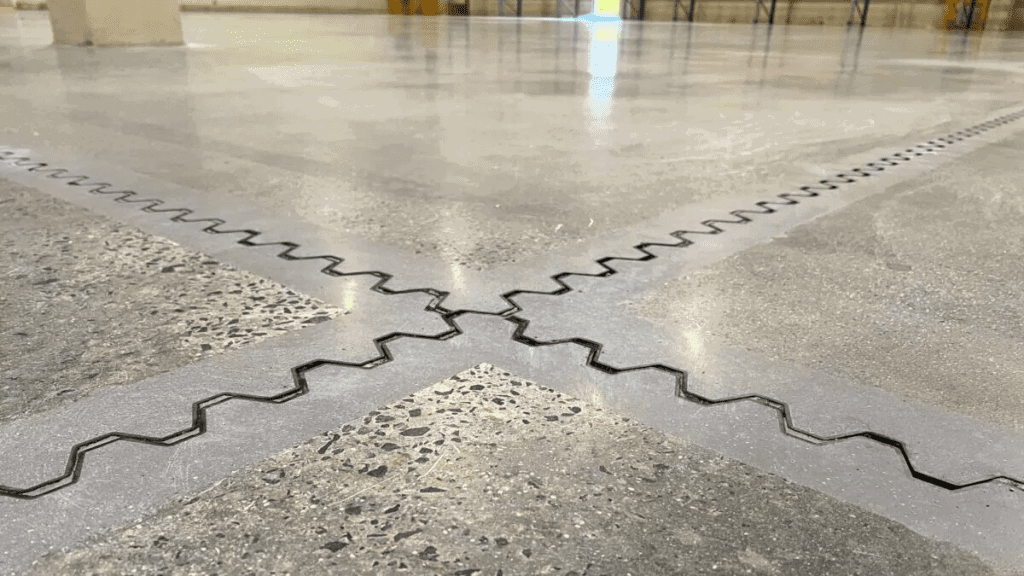

Joint Fillers

The choice of joint filler material for polished concrete floors depends on various factors, including the type of joint, the expected movement in the joint, and the desired aesthetics. Here are some standard options for joint filler materials on polished concrete:

-

Polyurethane Sealants:

Polyurethane sealants are popular for joint fillers in polished concrete floors. They are flexible, durable, and can accommodate some degree of movement in the joint. Polyurethane sealants also come in various colors, allowing you to match them to the concrete’s color and achieve a seamless appearance.

-

Polyurea Sealants:

Polyurea joint fillers are known for their fast curing times, which can minimize downtime during installation. They offer good adhesion and flexibility, making them suitable for narrow and wide joints.

Expansion or control joints are installed to prevent damage caused by concrete slabs expanding and contracting with high-wear traffic and preformed joint fillers to maintain the slab’s integrity and prevent debris from entering.

Signature AR from Permaban is a top-notch system for joint filling made of durable PVC. It is commonly used in industrial settings where joint movement is expected and where the edge of the existing slab needs reinforcement to prevent further joint damage.

Remember that the quality of the repairs and polishing work can significantly impact the final appearance and durability of the polished concrete surface. Investing time and effort into proper preparation and execution will yield the best results.