What quality control really means—and why it matters to you as a client

When you’re investing in a flooring system—whether epoxy, polished concrete, urethane cement, or a specialized industrial topping—you expect it to last. However, even the best materials can fail if the installation process isn’t controlled from start to finish.

At Applied, we’ve made Quality Assurance and Quality Control (QA/QC) a non-negotiable part of every project—because we’ve seen what happens when it’s ignored:

- Floors peel, blister, or crack within months

- Drains back up due to poor slope or leveling

- Joint fillers fail, causing damage to forklift wheels or robotic systems

- Projects run over budget and schedule due to rework

Our QA/QC system is designed to prevent all of that—and protect you.

How do we make it work for you?

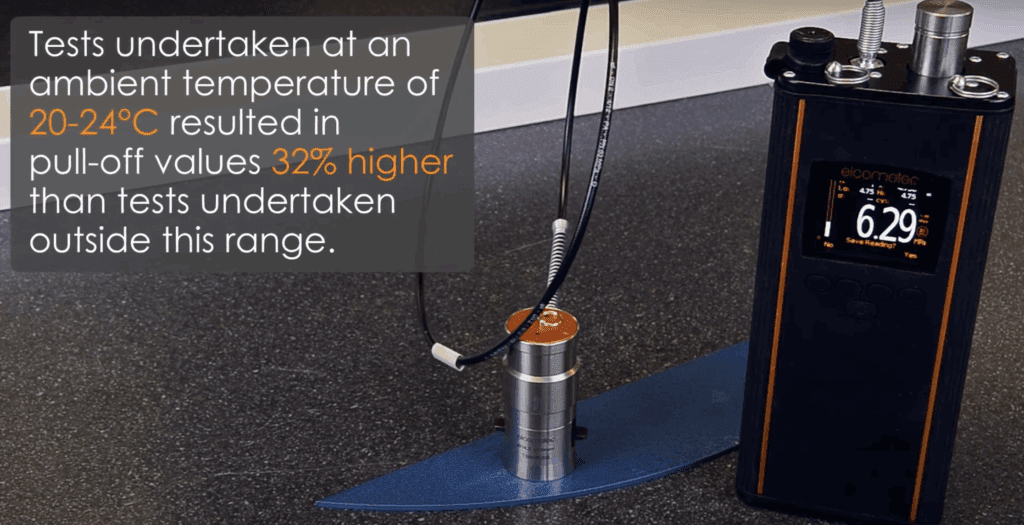

1. Pre-Installation Checks That Catch Problems Early. We verify site conditions before opening the first bag. We check and log moisture levels, slab flatness, surface profile (CSP), and temperature, preventing later surprises.

2. Product Validation and Application Oversight. From primers to topcoats, we ensure every material (Sika, Sherwin-Williams, Mapei, Euclid, Ardex, etc.) is installed exactly to spec—correct mix ratios, coverage rates, and cure times.

3. Joint Control and Drainage Assurance. We review all control joint locations, fill with proper materials (polyurea, epoxy), and verify drains’ slopes because poor detailing leads to puddling, breakdown, or safety hazards.

Real-Time Monitoring You Can Trust

We don’t wait until the job is done to check for quality—we monitor daily.

Our internal QA/QC program includes:

- Daily reports from the field with progress photos and workmanship logs

- Issue tracking in real-time, so minor problems never turn into significant delays

- Performance reviews that help us deliver consistent quality on every job, from Calgary to Halifax

As a client, this gives you transparency, accountability, and peace of mind.

You can feel confident knowing your project is:

- Installed to the highest industry standards (TR34, Fmin, CSP, etc.)

- Compliant with manufacturer warranties

- Backed by a contractor that takes ownership of results, not excuses

We Deliver Floors That Perform—and Stand the Test of Time

Whether you manage a food plant, logistics warehouse, or commercial space, your floors take a beating. Let’s ensure they’re built to handle it, with the quality control to match.

📩 Want to see how our QA/QC approach protects your facility from costly rework? We’d be happy to walk you through it.