Flatness (FF) and levelness (FL) are important quality measures for concrete slabs intended for polishing, particularly in applications where a smooth and uniform surface is desired, such as polished concrete floors. These measurements help ensure that the finished surface meets the required standards for flatness and levelness. You can use specific tools to measure FF and FL and follow established industry standards.

Understand the Definitions

-

Flatness (FF):

This refers to the variation in elevation of the concrete surface from a specified reference plane, typically a straightedge or laser level. FF is expressed in terms of the gap or distance between the reference plane and the highest point on the concrete surface and is usually measured in millimetres or inches.

-

Levelness (FL):

Levelness measures the variation in elevation of the concrete surface relative to a horizontal plane. It helps determine if the surface is flat across its entire area. FL is also typically expressed in terms of millimetres or inches.

Select the Right Tools

To measure a concrete slab’s FF (Flatness) and FL (Levelness), you’ll need specialized tools designed for this purpose. These measurements ensure that the concrete slab meets the required specifications and standards.

F-Number System:

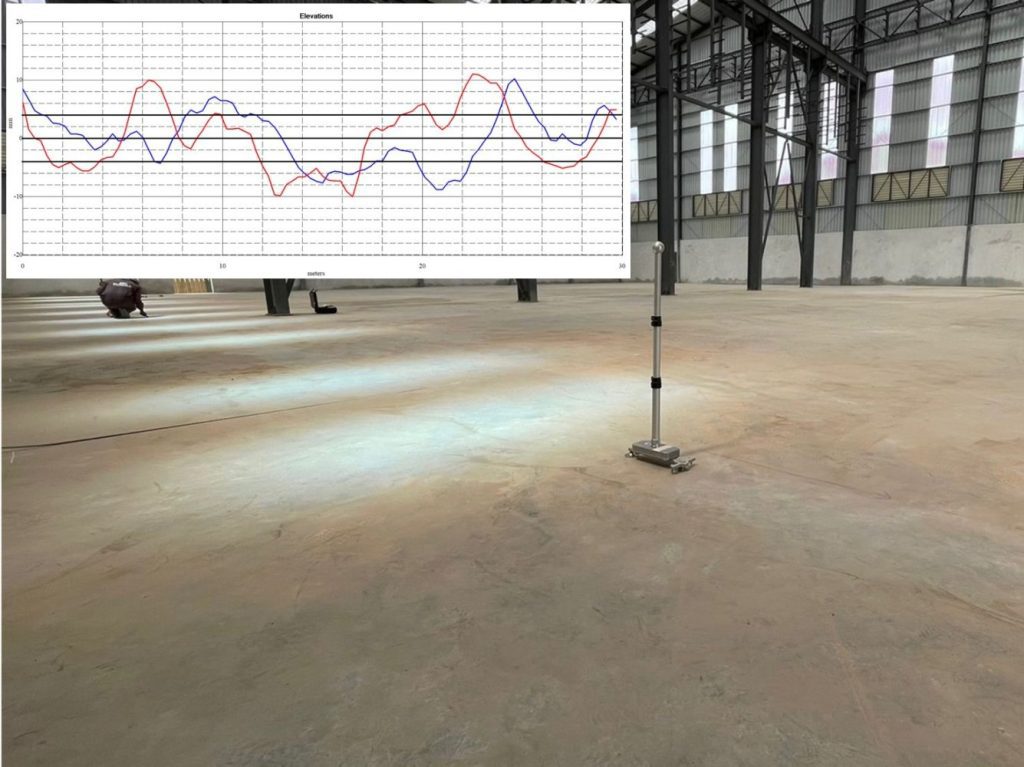

The F-number system is the industry standard for measuring FF and FL. It involves using specialized equipment, including a profiler and a dipstick (a bump cutter or gauge).

Dipstick:

This tool measures the levelness of the concrete surface. It’s a straightedge with sensors that detect variations in elevation.

Rotary Laser Level:

A rotary laser level is a useful tool for checking the levelness of a concrete slab. It emits a laser beam that rotates 360 degrees, providing a level reference point across a large area. Place the laser level at various points on the slab to check for levelness.

Digital Levels:

Digital levels, such as electronic inclinometers, can be used to measure the slope and levelness of a concrete surface with high precision. These devices provide digital readouts of angles and are handy for spot-checking specific areas.

String Line and Line Level:

For smaller projects or localized measurements, a string line and a line level can be used to check levelness. The string line is stretched between two points, and the line level ensures that it is level. The height of the string above the concrete can then be measured to check for levelness.

Automated Measurement FF and FL

Automated equipment can significantly streamline measuring concrete slabs’ flatness (FF) and levelness (FL). These tools often provide more accurate and efficient results compared to manual measurements.

FF/FL Profilers (F-number systems):

These are highly specialized machines designed to measure FF and FL. They consist of laser sensors mounted on a carriage that traverses the concrete surface. The sensors record elevation data at regular intervals and provide a detailed surface profile.

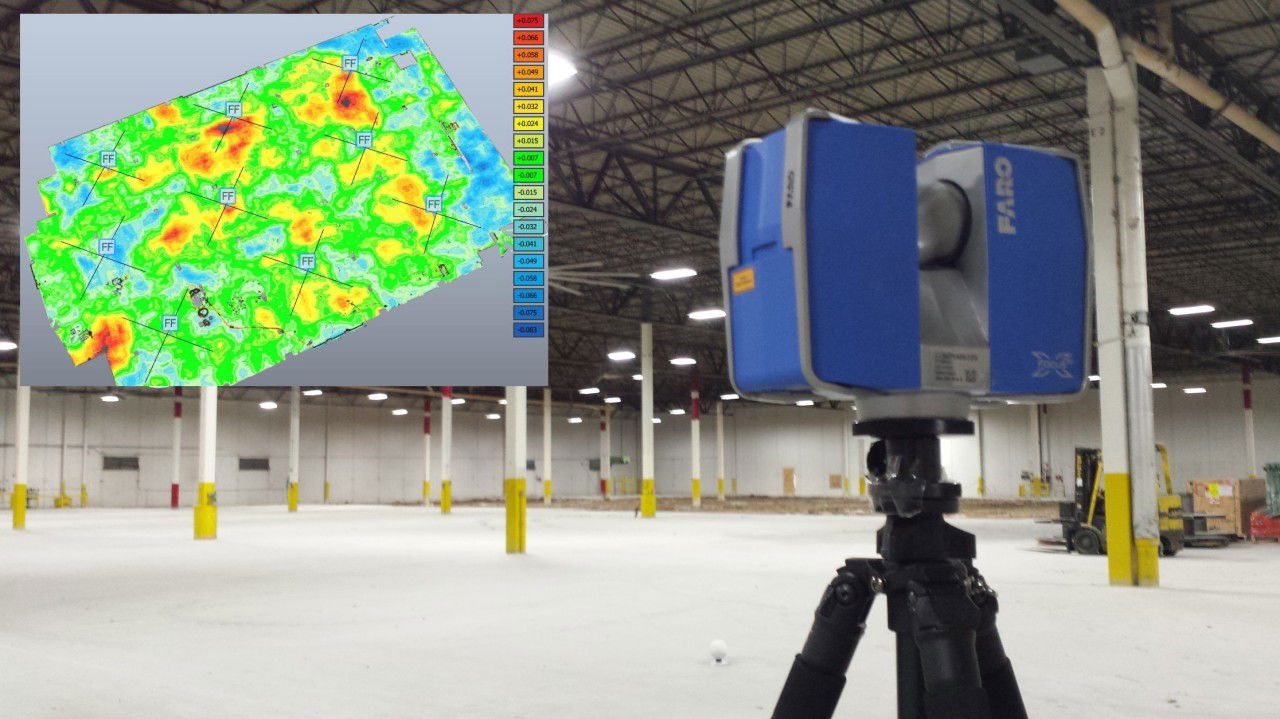

3D Laser Scanners:

3D laser scanners can capture detailed point cloud data of the entire concrete surface. While primarily used for creating as-built documentation, this data can also analyze FF and FL by measuring deviations from a flat and level reference.

Documenting Results

The ASTM E1155 method generates statistical information regarding floor surfaces. The test method results are used to establish compliance and can be used to evaluate the effect of different construction methods on resulting floor surface flatness and levelness.

If your measurements do not meet the required standards, adjustments, such as additional grinding or levelling, may be needed to achieve the desired FF and FL values. Keep detailed records of your measurements and any corrective actions taken. This documentation is often required for quality assurance and project compliance.

It’s crucial to follow the specific standards and guidelines provided for your project, as acceptable FF and FL values can vary depending on the application and project requirements. These measurements are essential for achieving a high-quality polished concrete surface.