Navigating the Challenges of Flooring for Very Narrow Aisle (VNA) Warehouses

Choosing the right flooring solution is critical when designing warehouse floors for Very Narrow Aisle (VNA) operations. However, a super-flat concrete slab might sound like the ideal choice; even the flattest slabs can fall short of the unique requirements for VNA trucks to operate efficiently and safely. Let’s explore why this is the case, the cost implications of different slab tolerances, and how to achieve the ultra-flatness required for optimal VNA performance.

Understanding the Cost Difference Between Regular and High-Tolerance Concrete Slabs

Regular Concrete Slabs with Low Tolerance

Standard concrete slabs in most warehouses are designed to handle general operations. These slabs typically have a low flatness and levelness tolerance, making them cost-effective, generally ranging from$5 to $10 CAD per square foot. While suitable for general forklift operations, they are inadequate for VNA trucks that require much higher flatness levels for safe and efficient navigation.

High-Tolerance Concrete Slabs for VNA Warehouses

For VNA warehouses, where aisle widths are significantly narrower, and lift heights are greater, floor flatness is paramount. High-tolerance slabs, such as those compliant withFmin100 standards, can cost anywhere from $20 to $40 CAD per square foot or more, depending on the specification and required flatness. This significant cost difference arises from the need for specialized materials, precise placement techniques, and advanced finishing processes to achieve the required flatness.

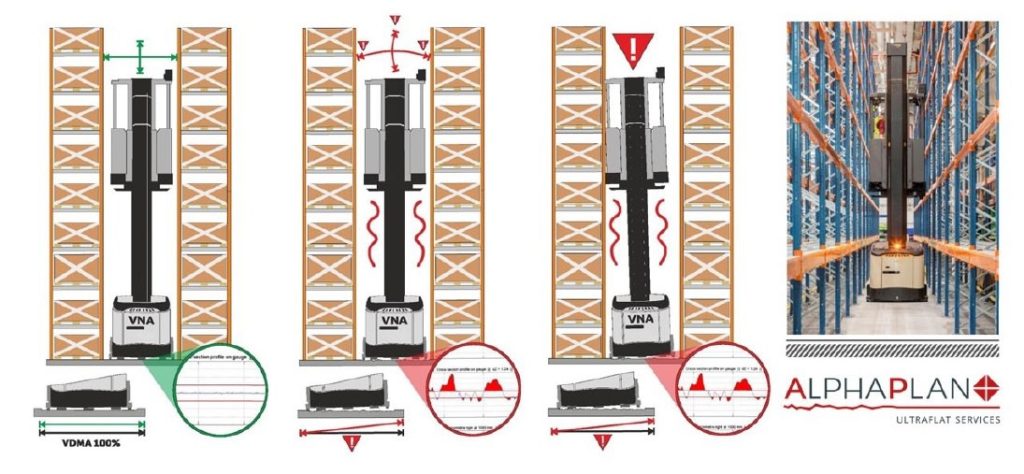

Why Even a Superflat Concrete Slab May Not Be Sufficient for VNA Operations

While super flat slabs are engineered for general warehouse use, they do not meet the stringent requirements of Fmin100 standards, which are crucial for VNA operations. VNA trucks, designed for very narrow aisles, rely on the highest possible flatness and levelness to prevent mast sway, improve stability, and ensure safety at high lift heights. Even slight deviations in floor flatness can cause trucks to tilt or sway, potentially leading to accidents, operational delays, and increased maintenance costs.

Measuring Flatness: The F-Number System and Fmin Standards

The flatness and levelness of warehouse floors are commonly measured using the F-number system:

– FF (Flatness Number): Indicates the bumpiness of the surface.

– FL (Levelness Number): Indicates the floor is level relative to its intended plane.

The Fmin system is more applicable to VNA warehouses. A Fmin100 slab, for example, is a specific flatness standard designed for very narrow aisle traffic. Achieving this level of flatness is critical to ensuring that the VNA trucks operate smoothly without any deviations that could cause damage or delays.

How to Achieve Fmin100 Flatness Levels

Achieving Fmin100 flatness requires several steps:

1. Precision Grading and Base Preparation:The foundation must be perfectly graded and compacted to provide a stable base.

2. Advanced Placement Techniques:Using laser-guided screeds and specialized finishing tools helps ensure even concrete distribution and minimizes surface undulations.

3. Grinding and Planing: Mechanical grinding and planing techniquescan be used post-placement to increase flatness to meet Fmin100 requirements.

4. Regular Monitoring and Measurement: Utilizing tools like the Face Dipstick or F-Meter during and after construction can help monitor and ensure the floor meets Fmin100 standards.

Maximizing Performance with the Right Floor Solution

Investing in a high-tolerance concrete slab designed specifically for VNA operations might seem like a significant upfront cost, but it pays off in the long run. A floor meeting Fmin100 standards ensures safer and more efficient operations, reduces maintenance costs, and prolongs the lifespan of both the floor and the VNA trucks. Measurements can be done with a fully automated robotic FloorProfiler.

Ensure your VNA warehouse operates at peak efficiency with a floor designed to match its demands. Make the smart investment in a high-tolerance slab and set your operations up for success!