In a technology-driven world where a single spark can cause catastrophic damage to delicate electronics or ignite hazardous environments, electrostatic discharge (ESD) flooring is more than just a surface—it’s a safeguard. For Canadian industries, the choice between dissipative and conductive ESD coatings isn’t just about functionality but resilience, safety, and efficiency.

The Quiet Protector: Dissipative Flooring

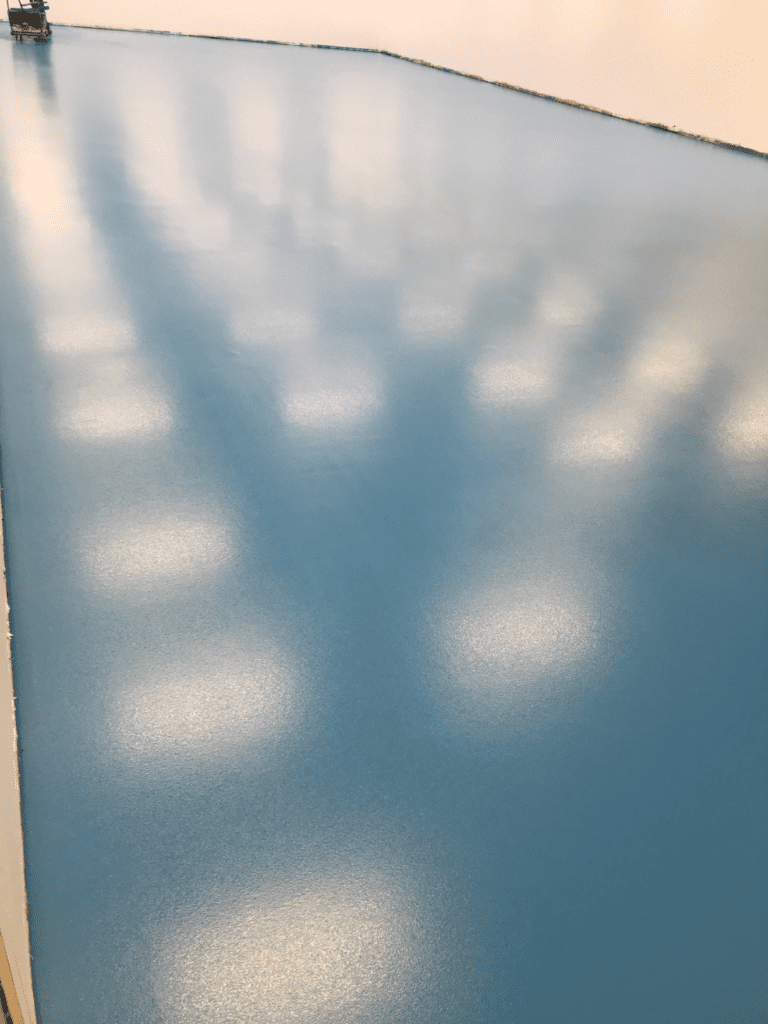

Picture a bustling electronics assembly line, precision instruments humming in a symphony of innovation. Beneath it all, dissipative flooring works silently, gently, and without drama, ensuring static charges find their way to the ground. With resistance levels ranging from 1 x 10^6 to 1 x 10^9 ohms, dissipative coatings provide a controlled pathway for static electricity.

This type of flooring is a favorite in environments where sensitive electronics need careful handling, such as research labs, semiconductor facilities, and testing centers. Its gradual discharge mechanism prevents sudden sparks that could disrupt delicate operations. From a safety perspective, it aligns with standards like IEC 61340-4-1, protecting both employees and equipment.

The Choices at Your Feet

Sikafloor®-260/270/222 W ESD Coating:

This durable, compliant coating maintains electrical conductivity throughout the system’s thickness and is formulated to be low in VOCs and odor, making it suitable for use in occupied facilities.

The Fast Responder: Conductive Flooring

Now imagine a cleanroom where even a microsecond delay in neutralizing static could compromise a batch of products. Enter conductive flooring with rapid static dissipation capabilities (resistance levels from 2.5 x 10^4 to 1 x 10^6 ohms). It’s a no-nonsense solution for high-stakes environments like data centers, explosive material storage, and advanced manufacturing facilities.

Conductive flooring complies with regulations such as ANSI/ESD S20.20 and exceeds expectations. It ensures that static electricity vanishes instantly, preventing sparks and keeping operations running smoothly.

Top Performers in Conductive Systems

Sikafloor®-262 AS/235 ESD/220 W Conductive

Meets regulatory ESD protection and workplace safety standards. It is also resistant to wear and tear, extending its lifecycle. Thus, it combines performance and durability for a cost-effective flooring solution.

PIP 200 ESD Conductive:

Compliant with ANSI/ESD S20.20 standards. Resistant to chemicals, abrasions, and impacts. Suitable for diverse industries and customized to performance needs.

When Safety and Efficiency Collide

For Canadian industries, the value of ESD flooring goes beyond compliance with Occupational Health and Safety (OH&S) standards. It’s about ensuring that the heart of your operations—the people and the technology—remains unharmed. ESD flooring significantly reduces the risk of static-induced accidents, extends the life of critical equipment, and cuts downtime caused by unexpected failures.

Beyond safety, there’s an operational advantage. Facilities that invest in advanced ESD systems see fewer interruptions and greater employee confidence. With coatings designed for easy maintenance and environmental friendliness, such as low-VOC options from Sika and PIP, these floors are as sustainable as they are reliable.

Lessons from the Field

Experience tells us that even the best flooring can fail without proper preparation. One cleanroom, for instance, faced delamination within months because moisture testing was skipped. The cost? Weeks of downtime and an expensive redo.

Another facility ignored grounding requirements, leading to inconsistent performance. The result? Equipment failures and lost revenue. These mistakes underscore a vital truth: ESD flooring isn’t just about the materials; it’s about meticulous installation and maintenance.

What Makes ESD Flooring Work

Professional Installation: +Certified installers ensure flawless application, reducing long-term risks.

Regular Testing:

Monitoring resistance levels helps identify issues before they escalate.

Proper Cleaning:

Monitoring resistance levels helps identify issues before they escalate.Use ESD-compliant solutions to maintain conductivity.

Grounding Infrastructure:

Monitoring resistance levels helps identify issues before they escalate.Ensure every connection is robust and reliable.

A Partner in Protection

Choosing the right ESD flooring flooring is about more than technical specs. It’s about partnering with systems designed to meet your needs and exceed your expectations. Whether you opt for the gentle touch of dissipative coatings or the swift action of conductive ones, the right choice will protect your operations, people, and future.

Are you ready to explore how ESD flooring can transform your facility? Let’s create a solution that is as dynamic as your industry.