The integrity of containment systems is paramount in industries dealing with hazardous chemicals. Both primary containment, which protects equipment and surfaces, and secondary containment, which serves as a safeguard against spills, demand the highest level of protection. Vinyl ester coatings are gaining widespread recognition for their unmatched chemical resistance, durability, and ability to contribute to sustainability goals.

Vinyl ester coatings are increasingly becoming the go-to solution for facilities needing high-performance containment systems, with real-world examples of their impact.

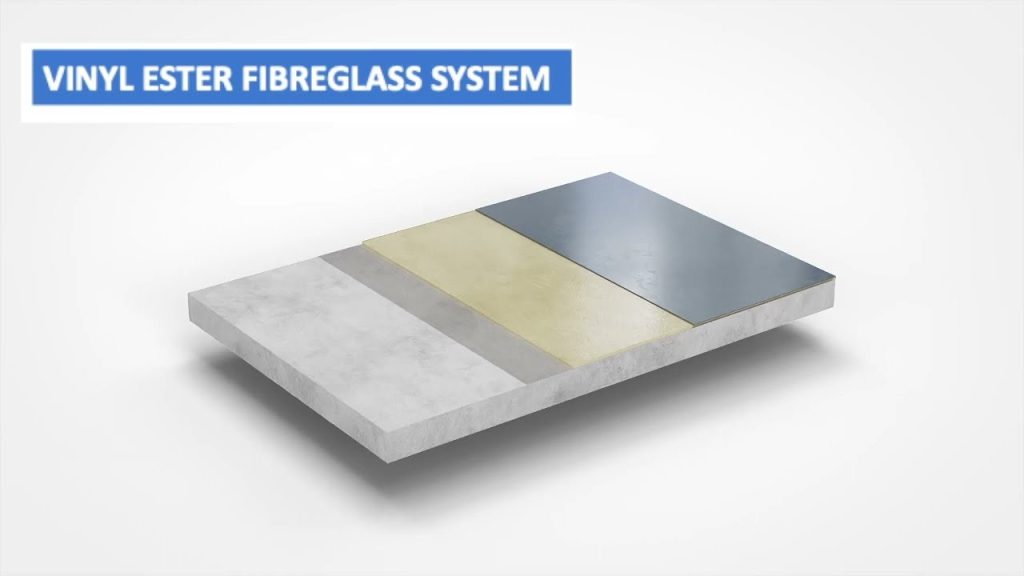

The Benefits of Vinyl Ester Coatings and Linings

Superior Chemical Resistance

Vinyl ester coatings provide a robust shield against various corrosive chemicals, including aggressive acids, alkalis, and solvents. This makes them essential for chemical processing, wastewater treatment, and refineries.

Durability and Longevity

Built with a hybrid molecular structure strengthened by epoxy, vinyl ester coatings provide toughness and long-lasting protection in extreme conditions. Facilities that have adopted vinyl ester technology report dramatic reductions in maintenance and longer intervals between repairs.

Increased Sustainability

Vinyl ester coatings contribute to sustainability by extending the life of containment systems, reducing waste from frequent repairs, and lowering the demand for new materials. By keeping containment systems intact, vinyl ester coatings lessen the environmental impact of material replacements and maintenance activities.

Resistance to Corrosion and High Temperatures

Vinyl ester coatings provide excellent resistance to corrosion and high temperatures, making them ideal for environments where other coatings may fail. This protection ensures the integrity of containment systems even when exposed to harsh chemical and thermal conditions.

Reduced Environmental Risk

In secondary containment, vinyl ester linings act as a critical barrier to contain any chemical leaks or spills. This protects the surrounding environment and helps facilities comply with stringent environmental regulations.

Cost Efficiency Over Time

Although vinyl ester coatings have a higher initial cost than some alternatives, their extended lifespan and resistance to damage drastically reduce the frequency of repairs and downtime. Over time, facilities experience significant cost savings.

The Disadvantages of Vinyl Ester Coatings

While vinyl ester coatings have many advantages, there are a few downsides to consider:

Shorter Shelf Life

Vinyl ester coatings have a limited shelf life, which requires precise planning and inventory management to prevent waste.

Higher Upfront Costs

The initial investment in vinyl ester coatings is higher compared to other coatings like epoxy or polyester resins. However, the long-term cost savings from fewer repairs and extended durability often outweigh the upfront costs.

Complex Application Process

Applying vinyl ester coatings requires expertise. Improper preparation or curing conditions can lead to coating failures, making skilled professionals essential for successful installations.

Odor and VOC Emissions

During installation, vinyl ester coatings can emit strong odors and release volatile organic compounds (VOCs), requiring protective measures for workers and proper ventilation.

Real-World Impact: Vinyl Ester Coatings in Action

- Chemical Plant in Texas: Vinyl ester coatings applied to the plant’s primary and secondary containment systems reduced relining frequency by 50%. This reduced material waste and helped the plant achieve ISO 14001 certification for environmental management.

- Refinery in Europe: Vinyl ester coatings in secondary containment systems helped prevent environmental contamination during a significant chemical spill. The facility reported that the coating’s resilience minimized cleanup efforts and reduced the overall environmental impact.

- Wastewater Treatment Facility in California: Switching to vinyl ester coatings extended the service life of the facility’s tanks by two decades. This shift improved operational efficiency and reduced repair-related waste, contributing to the plant’s long-term sustainability goals.

Why Vinyl Ester is the Future of Containment

Vinyl ester coatings are a smart investment in both safety and sustainability for facilities that handle hazardous chemicals. Their ability to withstand harsh chemicals, extreme temperatures, and corrosive environments makes them indispensable in chemical processing, petrochemicals, and wastewater treatment.

Vinyl ester coatings protect assets and contribute to a more sustainable future by reducing the need for frequent repairs, cutting maintenance costs, and helping meet environmental regulations.