Achieving a flawless finish in polished concrete begins with a foundation of exceptional concrete flatness. The levelness and smoothness of the concrete substrate play a pivotal role in determining the quality of the final polished surface. Concrete flatness refers to the uniformity of the surface profile, while waviness denotes variations in elevation over more considerable distances. Understanding and addressing these factors are essential for delivering polished concrete surfaces that exude excellence.

Importance of Concrete Flatness

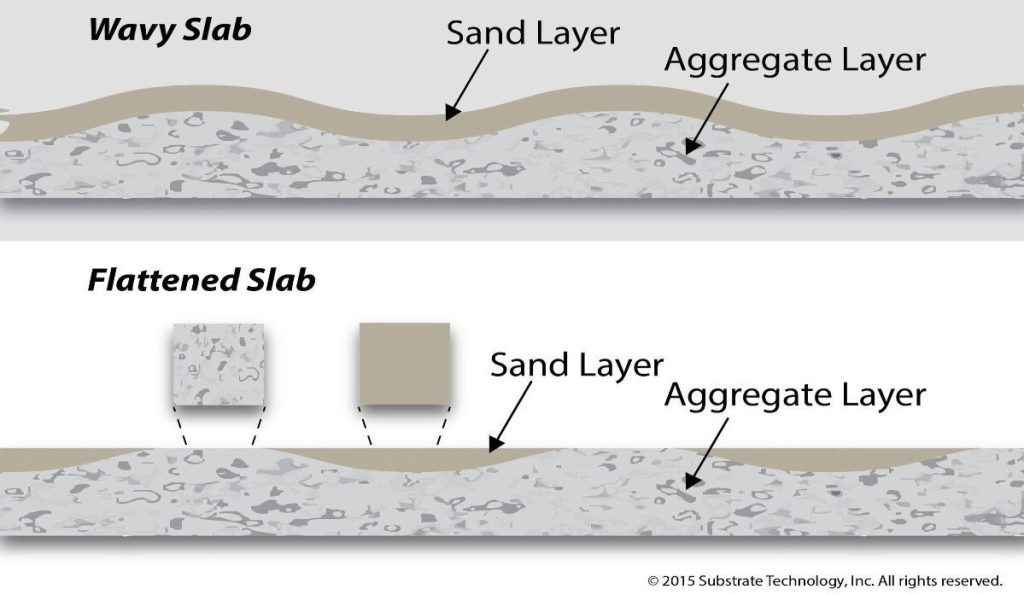

Concrete flatness serves as the canvas upon which the artistry of polished concrete unfolds. A level and smooth substrate provides the ideal starting point for the polishing process, allowing for uniform grinding and polishing. Any irregularities or deviations in flatness can result in consistency in the polished surface, detracting from its visual appeal and durability. Moreover, inadequate flatness can lead to difficulties in achieving desired gloss levels and clarity of reflection, compromising the overall aesthetic of the finished floor. In addition to waviness, inconsistent aggregate exposure due to different levels in the concrete substrate can further complicate the polishing process. Varying levels of aggregate exposure can result in uneven coloration and texture across the polished surface, disrupting the desired uniformity and aesthetics.

Dependence of Polishing Quality on Concrete Waviness

The quality of polishing is intricately linked to the level of concrete waviness. Waviness refers to broader undulations or irregularities in the surface profile, which can manifest as ripples, dips, or humps. These variations pose significant challenges during polishing, requiring additional grinding to achieve a uniform appearance. Excessive waviness can result in uneven gloss levels, visible inconsistencies in reflection, and diminished clarity of the polished surface. Furthermore, waviness can impact the longevity and performance of the polished concrete, as areas of uneven wear may develop over time in response to foot traffic and other stressors.

In conclusion, concrete flatness serves as the cornerstone of high-quality polished concrete, laying the groundwork for impeccable results. Achieving optimal flatness requires meticulous attention to detail during the placement and finishing of the concrete slab, as well as the use of precision instruments to assess surface profiles. By addressing concrete waviness and ensuring a level substrate, contractors can elevate the quality of polished concrete surfaces, delivering floors that embody excellence in aesthetics and performance.