The Importance of Environmental Conditions in Resinous Flooring Installations 🌡️💧

Proper control of temperature, dew point, and environmental conditions is essential for successfully installing epoxy coatings, polyurethane cement, polyaspartic, and MMA flooring systems. Mismanagement can lead to failures like poor adhesion, bubbling, or inconsistent curing. In this guide, we’ll cover:

- How to measure concrete and air temperature

- Differences in flooring systems and their environmental needs

- The impact of AC and HVAC systems on installation

- Best practices for maintaining ideal conditions

Measuring Concrete and Air Temperature

Accurate measurement of substrate and air temperatures is critical because these factors directly impact resinous flooring systems’ adhesion, curing, and longevity.

How to Measure Concrete Temperature

- Use an Infrared Thermometer

- Use a Surface Thermometer or Probe

- Prepare the Surface

- Monitor Multiple Points

Key Tip: Ensure the concrete acclimates to the environment for at least 24-48 hours before installation.

How to Measure Air Temperature

- Use a Digital Hygrometer or Thermometer

- Avoid Direct Heat or Cold Sources

- Measure Regularly

- Monitor Relative Humidity (RH)

Key Tip: Record readings to ensure conditions meet manufacturer specifications.

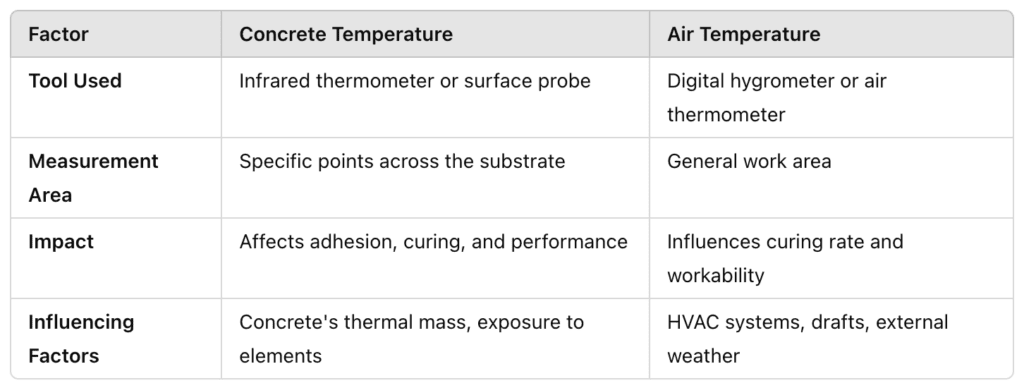

Concrete vs. Air Temperature: Key Differences

Understanding Different Flooring Systems

Each resinous flooring system responds differently to temperature and environmental factors:

1. Epoxy Coatings

- Substrate Temp: 10°C to 30°C (50°F to 86°F)

- Humidity Control: Maintain relative humidity below 85% during application.

- Key Risks: Condensation below the dew point causes adhesion issues and cloudy finishes.

- Impact of AC: Direct cooling can create condensation and surface defects.

- Best Practice: Keep substrate temperature at least 3°C (5°F) above the dew point.

2. Urethane Cement (UC)

- Substrate Temp: 5°C to 30°C (41°F to 86°F)

- Key Risks: Low temperatures slow curing; high temperatures speed it up, reducing workability.

- Impact of AC: Rapid cooling can disrupt curing in high-humidity spaces.

- Best Practice: Use heaters or dehumidifiers to maintain stable conditions.

3. Polyaspartic Coatings

- Substrate Temp: 10°C to 30°C (50°F to 86°F)

- Key Risks: Rapid curing in high temperatures can cause uneven results.

- Impact of AC: Drafts can accelerate or delay curing inconsistently.

- Best Practice: Avoid installation under direct airflow from vents.

4. Methyl Methacrylate (MMA)

- Substrate Temp: -20°C to 30°C (-4°F to 86°F)

- Key Risks: MMA works well in cold conditions but can be affected by humidity.

- Impact of AC: Not critical in cold conditions but can introduce condensation in warm areas.

- Best Practice: Precondition materials and ensure proper ventilation.

Why Dew Point and Humidity Matter

The dew point is the temperature at which moisture condenses on surfaces. If the substrate temperature falls below the dew point, condensation can occur, causing:

- Poor adhesion

- Surface bubbling or craters

- Cloudy or uneven finishes

Best Practice: During installation, always ensure the substrate temperature is at least 3°C (5°F) above the dew point.

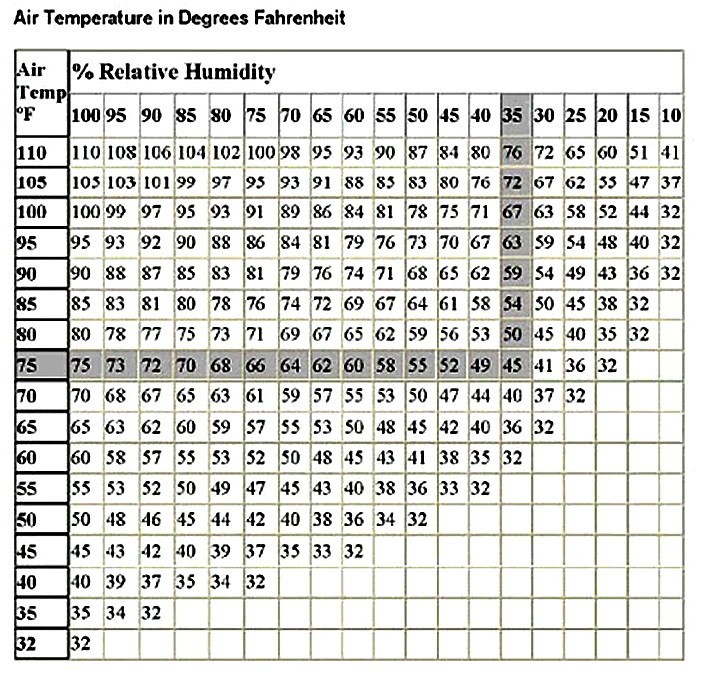

When the air temperature is 75°F, and the room’s relative humidity is 35%, the dew point is calculated at 45°F. This means that if your floor temperature drops to 45°F or lower, coating the floor becomes risky. Most technical data sheets recommend avoiding floor coating within 5°F of the dew point to prevent problems.

Why? At or below the dew point, condensed moisture can form on the concrete slab’s surface, leading to issues such as poor adhesion, improper curing, and compromised coating film integrity.

Additionally, it’s essential to understand the relationship between relative humidity (RH) and the dew point. At 100% RH, the dew point equals the air temperature. This is because, at full saturation, the air can no longer hold any more moisture. For instance, at 100% RH and 85°F, a wet rag placed outside will not dry. The air is already fully saturated, leaving the moisture from the rag with no way to evaporate.

Understanding these concepts is essential to ensure successful floor coating applications and avoid costly mistakes caused by environmental conditions.

Managing AC and HVAC Systems

- AC Risks: Direct airflow can cause uneven cooling, condensation, or contamination.

- Best Practice: Redirect vents or turn off HVAC systems in critical areas during application.

Best Practices for Resinous Flooring Installation

- Measure Temperatures Accurately: Use infrared thermometers for concrete and hygrometers for air.

- Stabilize the Environment: Use heaters, dehumidifiers, or fans to maintain ideal conditions.

- Plan for Seasonal Changes: Monitor temperature and humidity throughout the workday.

- Log Measurements: Keep detailed records to ensure compliance with manufacturer specifications.

Key Takeaways

- Temperature, humidity, and dew point control are essential for flawless installations.

- Each resinous system (epoxy, polyurethane cement, polyaspartic, and MMA) has specific environmental requirements.

- Accurate measurement and proper environmental management prevent costly mistakes.

Need expert help with your resinous flooring project? Contact us today for professional advice and flawless installation!